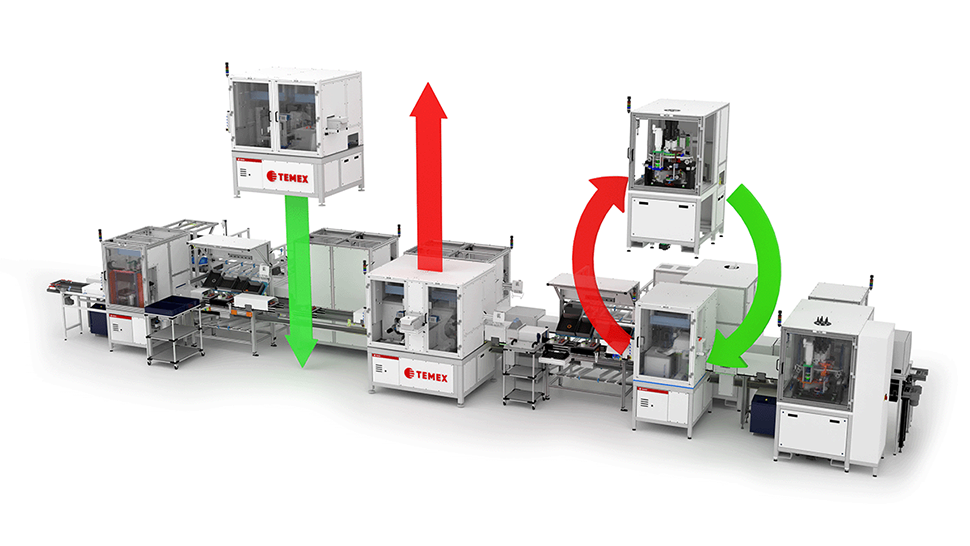

Modular automated production lines

Our flexible and scalable systems enable rapid adaptation to different production requirements and changes in production.

Modular Automated Production Lines

⇒ An Efficient Approach to Modern Manufacturing

TEMEX supplies innovative solutions enabling rapid adaptation to production requirements and process changes.

Modular production lines incorporate independent units, which combine, rearrange, or expand as required.

Modern manufacturing environments demand flexibility, efficiency, and responsiveness to market changes;

these systems deliver on these criteria.

Why choose TEMEX modular production lines?

Flexibility – Modules reconfigure easily. Operations involving small-batch production and frequent product changes benefit from this design.

Scalability – Production lines expand incrementally through the new modules addition . Complete system overhauls remain unnecessary, and costs are managed effectively.

Simplified Maintenance – Each module permits independent servicing or replacement, thereby reducing downtime and simplifying maintenance tasks.

Fast Implementation – Installation and commissioning occur rapidly, which shortens the production start-up time.

Lower Initial Investment – Incremental expansion minimizes the initial financial burden.

Versatility – Modules adapt to various production processes such as assembly, packaging, testing, and quality control, providing valuable adaptability as production needs change.

Typical modules in an automated production line:

1. Conveyor modules: They transport material or products between stations.

May include belt conveyors, roller conveyors or robotic carts.

2. Handling modules: Robots or mechanical arms for handling parts or products.

Equipped with special grippers or tools.

3. Assembly modules: Stations for assembling parts or components.

May include pressing, bolting, gluing or welding.

4. Inspection modules: Cameras, sensors or measuring equipment for quality control.

They detect defects or deviations from specifications.

5. Packaging modules: Automatically pack products into boxes, bags or onto pallets.

6. Storage modules: Automatic storage systems (AS/RS) for storing materials or finished products.

7. Software modules: Control systems (e.g. PLC, SCADA) for coordination and monitoring of the entire line.

Integration with ERP or MES systems for production control.

Contact us regarding your project, we would be happy to design for you a tailor-made solution.