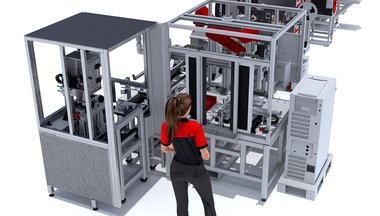

Robotic EGR valve cooler assembly line – 1st generation

Robotic assembly line with six workstations for the assembly of several types of EGR valve coolers

Robotic EGR valve cooler assembly line – 1st generation

Project: Robotic cooler assembly line

Number of positions in the device: 6

Term of delivery: 2016

PARAMETERS:

Length: 3200 mm

Depth: 2600 mm

Height: 2600 mm

Robots: Staübli TX90; Fisnar F5200N

Line cycle: 180 sec/pc

FEATURES:

The equipment works as one complete unit, which uses six separate workstations (positions) to progressively assemble the final product, the cooler for the EGR valve.

It consists of a total of 6 + 29 components:

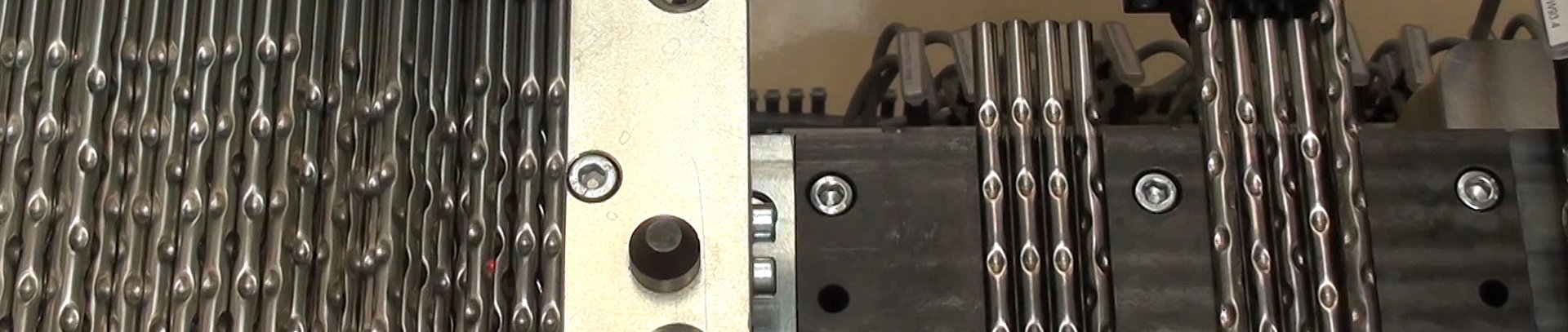

1 × Outer casing; 1 × Bottom flange; 1 × Upper flange; 1 × Bypass tube; 2 × Cap (further divided into an upper cap and lower cap) and 29 × Tubes

DESCRIPTION OF THE WORKSTATIONS:

The operator in Position 1 installs all parts except the tubes. The tubes are automatically loaded from exchangeable containers (changed by the operator) by the manipulator in Position 2. The finished and pasted piece is returned to the Station 1, where the operator takes it and puts/packs it in boxes at this position. The machine always processes one product, while the operator can take/add parts to produce another product.

Line description (view from the top):

A) Position 1 – Loading input components by the operator onto the turntable (2 positions) + Camera control

B) Position 2 – Loading the tubes

C) Position 3 – Outer casing calibration

D) Position 4 – Threading the tubes through the caps and tamping them

E) Position 5 – Pasting + Camera control

F) Position 6 – Mounting the upper and lower flanges