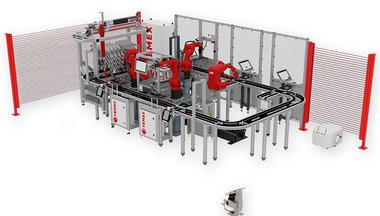

Small robotic workstation

Modern presentation of an "Industry 4.0" solution

SMALL ROBOTIC WORKSTATION

Project name: Small robotic workstation

Realisation: 2019

BASIC CHARACTERISTICS

For the needs of teaching students of the UTB-Faculty of Applied Informatics in Zlín, we have delivered a complete material flow simulation workstation, mainly for the purpose of reading Cartesian coordinates and other data within a comprehensive technological workplace. A wheeled autonomous mobile Omron robot (OEM LD-60) and a YuMi collaborative robot (IRB 14000) were used as output peripherals for material transfer for the purpose of cooperation with another workplace in the UTB facilities.

DESCRIPTION

The teaching laboratory robotic workstation is based on a core robotic system to which modular devices for individual operations can be added. The workstation is used to acquire knowledge and skills in the field of industrial robots with application to basic control of material flow kinematics.

All basic and modular workstations are interconnected and can communicate and cooperate with each other thanks to hardware (HW) and software (SW) control systems extended to allow their interconnection with the PLC control system and with a personal computer (PC) based supervisory control system (SCS), which allows the measurement of all variables relevant to the kinematic problems of the system.

Key benefits of our solution:

- Modular solution (easy and quick reconfiguration of the teaching station)

- A typical presentation of the current "Industry 4.0" solution

- Comprehensive learning workplace

- Practical presentation of SW and HW within the study