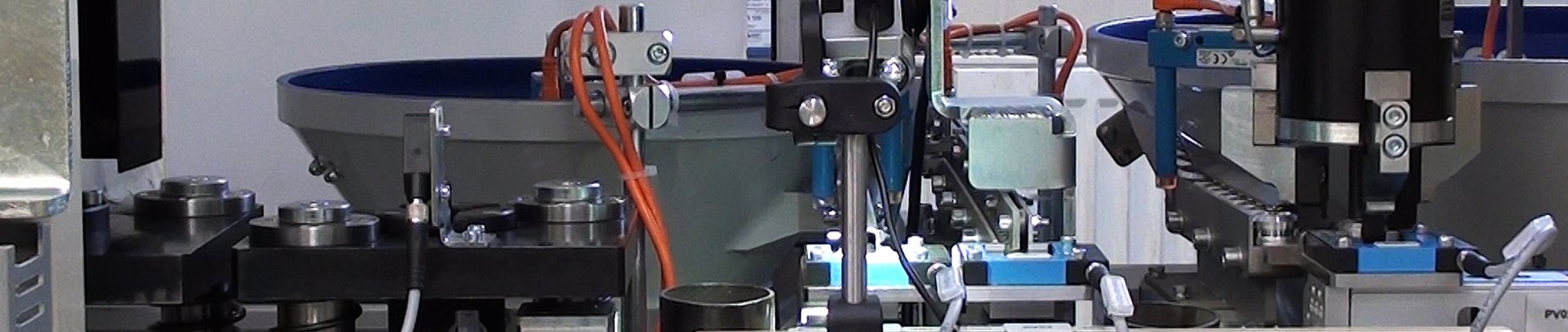

Machine No.1 – automatic assembly of the V-seal cartridge

No. 1 machine of semi-automated production line for assembly of 3rd generation Audi EGR valve with subsequent adaptation for the alternative assembly of the 2nd generation EGR valve.

Machine for the automated assembly of the V-SEAL CARTRIDGE

Project: Assembly line for the EGR valve – Audi V6

Number of workstations within the machine: 6

Term of delivery: 2015 – 2016

PARAMETERS:

Width: 2030 mm

Depth: 1900 mm

Height: 2000 mm

Operating pressure: 0.6 MPa

FUNKCE ZAŘÍZENÍ:

This machine represents fully automated device at the start of EGR valve production. Its purpose is the automated production of the V-SEAL CARTRIDGE:

1) 2× V-Seal

2) 1× Cartridge

3) 1× Washer

WORKPLACES´ EQUIPMENT:

The equipment uses vibrating feeders to move and orientate the individual components from the cassette to the collection points. Then, the individual parts are removed using a gripper and transferred in a horizontal position to the assembly jig. After assembly, the entire configuration is moved to the crimping jig, where the presence of components is checked and the final crimping takes place. After inspection, the finished configuration is automatically pushed into the OK or NOK chute, which leads to the collection drawer.

DESIGN OF THE MACHINE:

- The lower part is made of 60x60x6 steel beams, in the upper part ITEM beams

- Solid and polycarbonate panels – as fixed surfaces or as doors

- Workplaces protected with electric security locks or bolted connections

- Separate trolley with a hydraulic unit

- Electrical switchboard with integrated operator panel and controls